Selecting Screen Printing Inks: A Guide to Ink Perfection

Hey there, fellow ink enthusiasts! If you’re anything like me, you know that the world of screen printing is a colorful adventure waiting to happen. Whether you’re a hobbyist, an entrepreneur, or just a guy who loves getting his hands inky, selecting the right screen printing inks can make all the difference in your projects. So, grab a seat and let’s dive into the world of selecting screen printing inks for perfection!

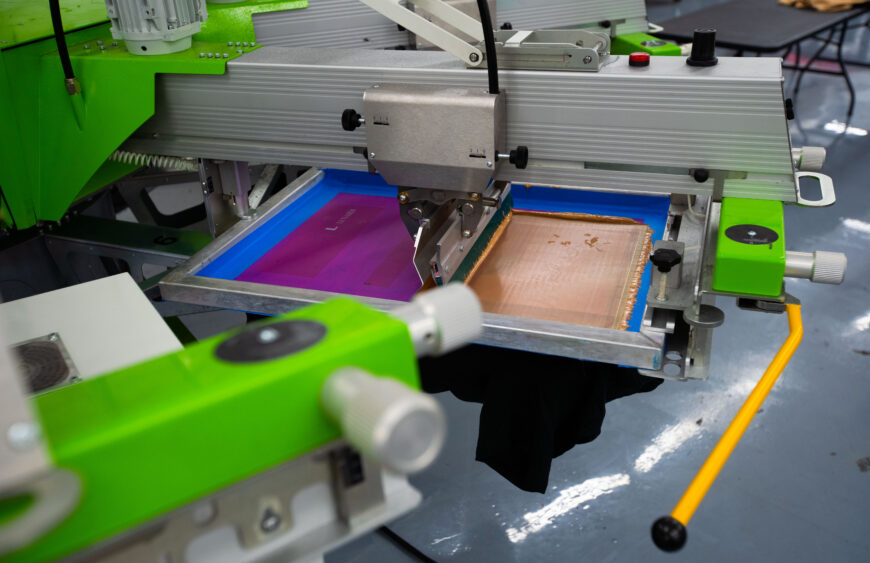

Understanding Screen Printing Inks

Alright, let’s start with the basics. You’ve got options, my friend – water-based, plastisol, discharge, and specialty inks. Each of these has its own superpowers, so think about what you’re printing and where it’s headed. Water-based inks, for instance, are like the eco-warriors of the ink world, great for that soft, vintage vibe. On the other hand, plastisol inks are the workhorses, with vibrant colors and durability that can withstand multiple washes.

Personal Anecdote: I remember a project where a buddy of mine wanted a super detailed design on his t-shirts. Water-based ink was my go-to for this one, as it gave the print that soft feel without sacrificing any of those intricate details.

Factors Influencing Ink Selection

Now, let’s talk about the fabric or material you’re working with. The substrate matters more than you might think. Ever seen a print that’s a bit… bleedy? Yeah, that’s when you haven’t matched the ink with the fabric. Think about texture, color opacity, and potential bleeding when you’re selecting. Oh, and if you’re all about saving the planet, water-based inks are your jam. They’re eco-friendly and perfect for eco-conscious dudes like us.

Design and Ink Compatibility

Picture this: you’ve got this fantastic design in your head, but if you don’t choose the right ink, it could turn into a disaster. For those intricate designs and tiny details, water-based inks or discharge inks might be your best bet. They’re like precision tools, ensuring your design pops without any fuzziness.

Personal Anecdote: I once had a client who wanted to print a super complex logo on a set of hoodies. Using discharge ink allowed me to capture every single detail, and the client was over the moon with the result.

Considering Fabric Characteristics

Let’s talk fabric, my dudes. Cotton, polyester, blends – they’re all in the game. Different inks play differently on different fabrics. For your classic cotton tees, water-based inks are your sidekick. But if you’re dealing with polyester gym shirts, plastisol inks are your trusty companions, as they handle the stretchiness like a champ.

Personal Anecdote: I remember this project where a local sports team wanted their logo on performance jerseys. Polyester was the name of the game, and I went with plastisol inks to ensure the prints stayed vibrant and didn’t lose their stretch.

Print Run Size and Production Speed

Alright, let’s talk business. If you’re printing a gazillion tees for a huge event, plastisol inks are your fast lane to success. They’re efficient and speedy, perfect for high-volume projects. But if you’re a one-man operation doing limited runs of custom tees, water-based inks offer that personalized touch without compromising quality.

Personal Anecdote: Back in the day, I got a massive order for a company’s annual event. Plastisol inks were my saving grace; they held up beautifully under pressure, and I managed to meet the tight deadline without breaking a sweat.

Curing Methods and Ink Performance

Ah, curing – the secret behind ink staying put. Different inks have different curing needs. Plastisol inks require heat curing, while water-based inks can air dry. Make sure to follow the recommended curing process for the ink you’re using. Improper curing can lead to faded colors and designs that don’t last as long as they should.

Budget Considerations

Let’s be real, budget matters. But here’s the thing: you don’t have to sacrifice quality for the sake of your wallet. Consider your project’s scope and choose your ink accordingly. Water-based inks might seem a bit pricier, but if you’re aiming for that premium feel, they’re worth every penny.

Personal Anecdote: I once had a client who was on a tight budget for a charity event. We went with water-based inks, and even though they were a bit more expensive, the quality of the prints was a game-changer. The attendees loved the soft, high-end feel of the shirts.

Maintenance and Care of Printed Items

Alright, you’ve put your heart and soul into these prints, so let’s make sure they stay looking fly. Follow the care instructions for each ink type to ensure the longevity of your masterpieces. Proper care can mean the difference between prints that fade after a few washes and those that stay vibrant for years.

Conclusion

So, my ink-loving amigos, there you have it – a crash course in selecting screen printing inks. From water-based to plastisol, substrate considerations to design compatibility, we’ve covered it all. Remember, it’s not just about slapping ink on fabric; it’s about creating wearable art that tells your story. So go ahead, get creative, and choose those inks like the screen printing rockstars you are. Your prints will thank you for it!

CONTACT US

‘

Recent Posts

- How to Choose the Right Custom Screen Printing Service for Your Needs

- Top Industries That Benefit from Custom Screen Printing Services

- Top Signs Your Business Should Outsource Screen Printing Services

- Benefits of Screen Printing Outsourcing for Small Businesses

- Common Mistakes to Avoid When Ordering Custom Screen Printing Services

BY SERVICE